IBC container covers and heaters. A wide range of heaters, jackets and covers all designed for the standard 1000 litre ISO IBC container that is one of the most popular ways of moving and storing a wide range of chemicals and foodstuffs.

IBC Container Heaters and Covers

The range below includes waterproof covers through to insulated jackets and heaters designed to maintain the viscosity of various substances.

IBC Top cover

The IBC Top Cover is a universal lid that fits any standard 1000L IBC container.

The top cover can be used together with the IBC Container Heater or the IBC Insulation Body Cover.

Using the lid together with a heater or insulation cover will minimise heating loss and help heating faster or maintaining temperature for a longer period of time.

The top cover has a strategically placed Velcro pad to access the top opening of the IBC container.

Technical specifications:

- Cordura material with Teflon coating.

- Water-repellent.

- Chemical resistant.

- Standard Size: 1000L

| Model | Size | Description: |

| 11-9861D | 4400 x 1000 mm | IBC Top Lid |

Waterproof cover for IBC Containers

This waterproof PVC cover is perfect to secure an IBC container against water in moist environments. The seams on the cover are welded, which makes the cover perfectly waterproof.

The IBC cover is designed in a sizing that makes it possible to have an IBC Container Heater attached to the container underneath the cover, which makes it possible to safely heat contents in the container even in wet weather or in moist conditions.

The IBC Cover is produced in durable PVC plastic and is easy to attach and detach to an intermediate bulk container (IBC).

The cover easily folds for minimal storage space.

Technical specifications:

- Produced in durable PVC materials.

- Welded seams for optimal waterproofing.

- Can be used with an IBC Container Heater.

| Model | Size | Description: |

| 11-9861E | 4400 x 1000 mm | Waterproof PVC cover |

IBC Thermal Bubble Wrap Cover

IBC bubble foil insulation covers are designed to isolate and maintain the temperature of an IBC Container (Intermediate Bulk Container).

These thermal IBC aluminium bubble wrap covers are designed to provide optimal protection from solar radiation, blocking the direct sunlight and deflecting the radiation and the heat so that the containers can be transported and/or be placed outdoor without damage and overheating from the sun's rays.

IBC bubble wrap covers are made of a metallic aluminium outer layer, which deflect the sun rays and a bubble wrap interlayer that helps to create space between the outer layer and the container, resulting in minimal to no heat transfer from the outside.

The Insulation cover is a one-piece cover, which is easily installed by pulling it down over the IBC container – the insulating cover has a Velcro input from the top so that the IBC container top lid easily can be accessed.

Technical specifications:

- Metallic aluminium inner- and outer.

- Bubble wrap foil interlayer.

- Perfect heat and radiation blocking.

- Standard size: 1000L

| Model | Size | Description: |

| 15-1736 | 4400 x 1000 mm | IBC Bubble Wrap Cover |

IBC Insulation Cover

The IBC insulated cover is designed to insulate and maintaining temperature inside an IBC intermediate bulk container. As for standards, this insulation cover fits a standard 1000 litre containers but also available for 1250 litres and 640 litre containers.

The standard insulation cover can also be used with an IBC Foil heater to speed up the heating process. In this way the insulation cover helps to insulate the container and speeds up the heating process.

The cover is designed in quality nylon materials, making the cover repellent to water.

The insulation cover is a full-size cover with a lid and equipped with Velcro pads, which makes it is effortless to attach or detach to a container. Furthermore, there are strategically placed Velcro pads to access the natural openings on the IBC container.

Technical specifications:

- Nylon materials.

- Water-repellent.

- Integrated lid.

- Strategically placed Velcro access pads.

- Standard Size: 1000 L

- Also, available in 1250 L and 640L.

| Model | Container | Size | Description: |

| 15-1740 | IBC 1000L | 1200 x 1000 x 1140 mm | Full IBC Insulation Cover |

IBC Insulation Body Cover

The IBC insulation body jacket is designed to insulate and maintaining temperature inside an IBC intermediate bulk container. As for standards, this insulation cover fits a standard 1000 litre containers.

The insulation jacket is designed in quality nylon materials and equipped with 4 quick release buckles for easy installation. This design allows the cover to be used with an IBC Container Heater - just attach and power on the container heater first and then the insulated body cover as an outer layer. Tighten the straps, and you will get a faster heating process. If you wish for an ever faster heating, an IBC Foil heater can be placed in the bottom of the IBC container.

In addition to heating or maintaining temperature, you can also add a top lid to the body cover.

Technical specifications:

- Nylon materials.

- Water-repellent.

- Adjustable straps.

- Quick release buckles.

- Standard Size: 1000L

| Model | Size | Description: |

| 13-1432 | 4400 x 1000 mm | IBC Insulation Cover |

IBC Container Heater, 3 Thermostats

When at room temperature, many materials often become viscous, which makes them harder to discharge from an IBC (Intermediate Bulk Container). In specific syrup, sugar, fats and others are difficult to discharge and often result in wasting products due to the thick viscosity not being able to leave the container.

This can end up being an expensive process unless you heat the (IBC) container first to make materials smoother and less viscous.

An IBC heating jacket is the perfect solution when it comes to quickly and effectively heating up fluids and materials, making them straightforward to empty from a container with minimal to no waste product.

The IBC heater is produced with either 1, 2 or 3 thermostats, all adjustable from 0 to 90 °C, making the container heater very fast and safe to heat liquids and maintaining the wanted viscosity for the content in the container.

The IBC heater jacket is designed in a durable and long-lasting high quality lightweight design and the construction together with quick release buckles makes the container heater easy to attach to any standard 1000L container.

This also makes this heater perfect to use when transporting 1000L containers with content that requires specific temperatures or viscosity.

TIP! For a faster and optimal heating process, we recommend using the IBC insulated lid (sold separately). The lid easily attaches to the top of the container, reducing waste of heat.(Shown above)

Container heating jackets are an ideal supplement to container heating cabinets, where the jacket is mounted to a single container. The container heating jackets can also be used with heating cabinets or heating ovens, making transportation of a heated container much easier and the heat loss minimal to none.

The container heater can be used to heat a variety of liquids, e.g. water, resin, oil, diesel fuel and many other industrial liquids and allows them to be poured or pumped with ease.

IBC Container Heater 2 Thermostats

- 11-9860 IBC Container heater 1000 L

- Size 4400-1000 mm

- 230V 2 x 1000 W

- 2 x Thermostat digital 0-90ºC

- 3 m. power cable

IBC Container Heater 1 Thermostats

- 11-9860A IBC Container heater 1000L

- Size 4400-1000 mm

- 230V 1300W

- 1 x Thermostat digital 0-40ºC / 0-90ºC

- 3 m. power cable

| Models | Dimensions | Voltage / Power |

| 11-9860 | 4400 x 1000 mm | 230V 2x1000 W |

| 11-9860A | 4400 x 1000 mm | 230V 1300 W |

| 11-9861 | 4400 x 1000 mm | 110V 2x1000 W |

| 11-9861A | 4400 x 1000 mm | 110V 1300 W |

| 11-9861B | 4400 x 1000 mm | 230V 3x1000 W |

| 11-9861D | Insulation lid | |

| 11-9861E | ||

| 13-1432 | Insulation cover |

ATEX IBC Container heaters

ATEX IBC Container heaters is a special heater type designed and approved to Ex Zone 2 compliance with 94/9 / EC (ATEX). The container heaters are perfect to safely heat and keep fluids frost free in an IBC container.

Technical specifications:

- Gentle and uniform heat transfer due to a dynamic and level depended on heat emission

- Extended protection grade IP54 and hydrophobic materials

- Complete PTFE- (Teflon®) coating for a maximum long-life cycle and highest reliability against bases, acids, solvents, etc. – free of silicone.

- Circumferential (360º C) belts with adjustable buckles, ensuring an optimal fitting and easy handling

- Real 3-dimensional design for an optimal fitting and heat transfer

- Nominal voltage: 115 or 230VAC, 50-60Hz

- Heating element: Self-limiting

- Power Connection: H07BQ-F, PUR coated, orange, acc VDE 0282 part 10 / HD 22.10

- Temperature Sensor: PT100 / Thermocouple (optional): EEx-e or EEX-i

- Surface resistance: <3*10?Ω/m²

- Ambient Temperature: -15ºC…+35ºC

- Protection grade: IP65

- Directives and Norms: Atex directive 94/9/EG

- DIN EN 60079-0, DIN EN 60079-7

- DIN EN 60079-30

- DIN EN 13463-1

- Marking:ATEX ll 3G Ex e ll T5

| Models | Drum | Size | Volt | Watt |

| 12-1203 | IBC Atex | 4400 x 1000 mm | 230V | 1500 W |

| 12-1204 | IBC Insulated lid Atex | - | - | - |

| 12-1201 | PT 100 ATEX Sensor | - | - | - |

| 12-1201A | Temperature controller | ATEX Control box | - | - |

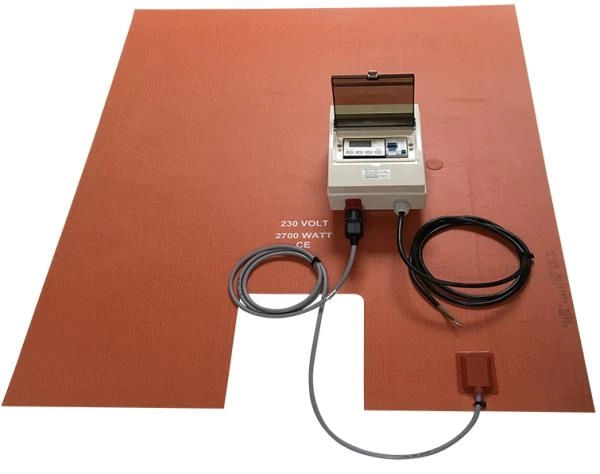

IBC Silicone Base Heater

An IBC silicone base heater is an effective and powerful way to heat up contents inside an IBC container.

The base heater is perfect for heating viscous or semi-solid products and making them straightforward to discharge from a container with minimal to no waste product.

The 2700W base heater can heat e.g. water in a fully loaded IBC container from 15 °C to 70 °C in less than 40 hours. If a faster heating process is required, we recommend adding an IBC insulation jacket to the process.

Silicone Base Heaters are produced in highly durable and long-lasting silicone materials that easily can withstand the weight of a fully loaded IBC Container. The base heater fits a variety of intermediate bulk containers (IBC containers) including IBC containers from Schütz, GNX, Mauser, Werit and Greif.

The silicone base heater is easy to install and to use - simply remove the bulk container from the IBC frame and install the silicone heater in the very bottom of the frame. Insert the container on top of the heater, fill the container, and you are all set to heat the contents. This also makes the heater ideal for heating and maintaining temperature while transporting the IBC container.

The IBC silicone base heater can be mounted with an adjustable digital temperature controller for safe and precise temperature controlling.

Technical Specifications

Durable and long-lasting silicone materials that easily withstands the pressure from a fully loaded IBC container.

- Dimensions: 1035 - 851 mm.

- Materials: 100% silicone.

- 1.5 meter power cord with no plugs.

- 0-150 °C PT100 Sensor System temperature controller (additional product).

- Heats water from 15 °C - 70 °C in less than 40 hours in a fully loaded IBC Container.

| Model | Thermostat | Unit | Size | Volt | Watt |

| 13-1436 | N/A | IBC | 1035-851 mm | 230V | 2700W |

| 13-1471 | 0-150 °C | Temperature controller | 200 x 120 x 120 mm. | N/A | N/A |

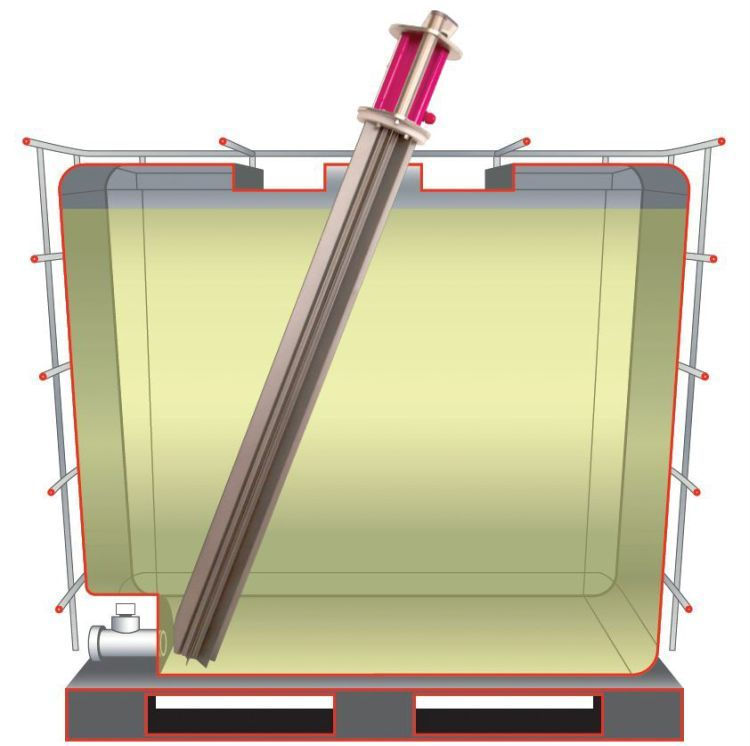

IBC Internal Heater

The Internal IBC Heater is a unique approach to heating viscous foodstuffs and chemicals within IBC Containers. Instead of traditionally heating from the outside, the heater is inserted inside the container with the base of the heating unit next to the outlet valve. This strategic placement makes it super easy to discharge the content from the IBC with little to no product waste.

It is designed to protect sensitive products, such as syrups, honey, treacle, molasses, fats and other viscous products that are difficult to process. Most products can be batched within a relatively short time, increasing efficiency and reducing downtime.

Features

- Fast internal heating

- Accurate temperature control

- All energy is transferred to the product

- Will not burn or scorch the product

- Sterilization option

Technical specifications:

- Designed for insertion into 1000 litres cubic IBC, but will also fit inside most IBC configurations.

- Adjustable temperature range from 0 °C to 70 °C using an easy-to-use controller on the top of the heater.

- 230/240 Volts - up to 2.4kW power output.

- Finned, food safe heating element that is inserted into the IBC, thereby heating the contents directly.

- Fast batching ability. Unique thermodynamic core that gives even temperature distribution along the heating extrusion,

- preventing thermal damage to the liquid contents of the IBC.

- Non-stick industrial strength Xylon coating for easy wash down.

- Carefully designed low Watt density to protect sensitive products.

- Lightweight, with stainless-steel handles for easy insertion and extraction.

- Even temperature distribution along the length of the heating extrusion.

- Coloured LED for power cycle and status indication.

- 16 Amp blue industrial power plug.

- Protective sleeve between the base of the control unit and the neck of the IBC to prevent ingress of contaminants.

- Robust Construction:

- IP67-rated body with potentiometer control mounted under protective see-through cover.

- The product is sealed to ensure that all the connections and components are waterproof.

- Robust IP67-rated aluminium case.

- Long life heating elements.

| Model | Container | Dimensions | Voltage / Power |

| 20-2904 | IBC | 1200x140x110 mm | 230V/240V Up to 2,4kW |

IBC Container Aluminium Foil Heater

Heating with an IBC Aluminium Foil Heater is an effective and low-cost method to heat the contents from the bottom inside an IBC container.

Foil Heaters are manufactured to individual specification for use in a variety of intermediate bulk containers (IBC containers) including IBC containers from Schütz, GNX, Hoover, Mauser, Werit and Greif.

Unlike normal IBC aluminium foil heaters produced with a paper inner, our IBC alu heaters are produced with a full-body aluminium construction, making our aluminium heaters more stable, durable and capable of withstanding the weight from a fully loaded IBC container.

The aluminium foil heater is straightforward to install and to use - simply remove the bulk container from the IBC frame and install the heater in the very bottom on the frame. Insert the container on top of the aluminium heater, fill the container, and you are all set to heat the contents. This also makes the heater ideal for heating while transporting the IBC container.

The aluminium foil heater is equipped with a bi-metal limiter, which limits the heater to a maximum of 50/60 °C or 70/80°, depending on the bi-metal installed.

The 1400W Aluminium heater can heat e.g. water in a fully loaded IBC container from 10 °C to 43 °C in less than 48 hours.

The aluminium foil heater is designed as a "single use" heater, which means that the product is to be discarded when used.

Technical Specifications

Reinforced aluminium foil with aluminium tube inside to withstand the pressure from the IBC container Bulk.

- Dimensions: 1095 - 895 mm.

- Material: Full-body aluminium foil.

- 1.5 meters power cable.

- Heats water in a fully loaded IBC tank from 10 °C - 43 °C in less than 48 hours.

- Designed for single use - to be discarded when used.

| Models | Thermostat / Limiter | Drum | Size | Volt | Watt |

| 12-1193 | 50/60º C | IBC | 1095-895 mm | 230V | 1080W |

| 12-1196 | 70/80º C | IBC | 1095-895 mm | 230V | 1080W |

| 13-1296 | 70/80º C | IBC | 1095-895 mm | 230V | 1400W |